In the realm of outdoor equipment, understanding the intricacies of your tool can significantly enhance your experience. This section aims to equip users with essential insights into operating and maintaining a specific chainsaw model, ensuring optimal performance and longevity.

Exploring various functionalities and features will empower users to navigate their tasks with confidence. By familiarizing oneself with the mechanics and recommended practices, individuals can ensure safe and efficient usage, while also minimizing potential issues that may arise during operation.

Furthermore, recognizing the importance of routine upkeep is crucial for preserving the tool’s reliability. With proper care and attention to detail, users can foster a productive relationship with their equipment, ultimately leading to greater satisfaction in every project undertaken.

Key Features of the Husqvarna 440

This section highlights the significant attributes of a popular chainsaw model, emphasizing its practical design and efficiency for various cutting tasks. With innovative engineering, this equipment caters to both amateur and professional users, ensuring a reliable experience in the field.

Power and Performance

The chainsaw is equipped with a robust engine that delivers exceptional power, enabling users to tackle challenging tasks with ease. Its advanced technology minimizes fuel consumption while maximizing output, making it an efficient choice for prolonged use.

User-Friendly Design

Ergonomically designed, this tool offers comfort during operation. Features such as an adjustable handle and lightweight construction enhance maneuverability, allowing for precise cuts and reducing user fatigue. Safety mechanisms are integrated to provide peace of mind while handling.

Maintenance Tips for Longevity

Regular upkeep is essential for ensuring the durability and performance of your equipment. By implementing a few straightforward practices, you can significantly extend its lifespan and enhance its efficiency.

- Regular Cleaning: Keep the exterior and internal components clean to prevent dirt accumulation that can hinder performance.

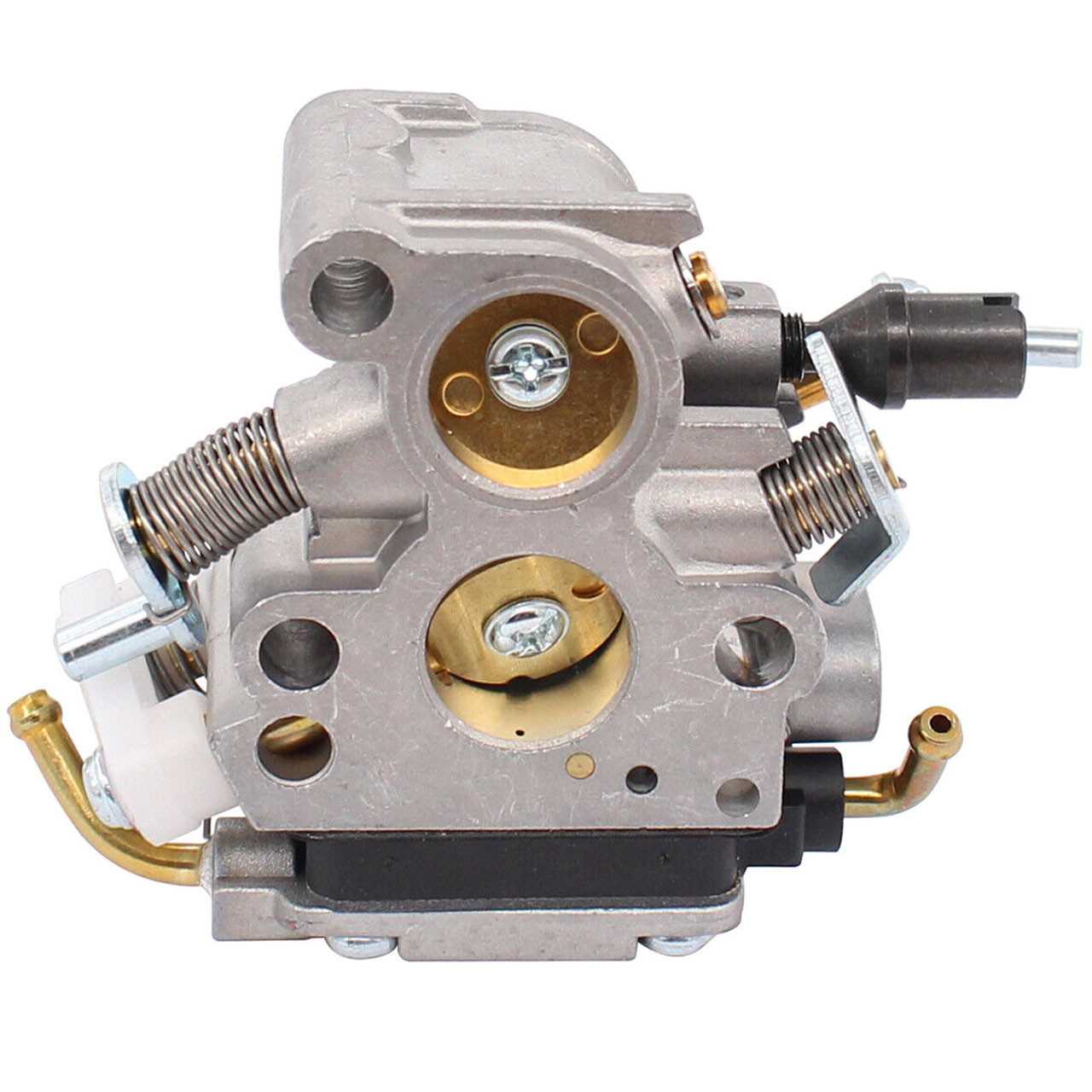

- Inspecting Parts: Frequently check vital components for wear and tear. Address any issues promptly to avoid further damage.

- Lubrication: Apply suitable lubricants to moving parts to minimize friction and prevent premature wear.

- Fuel Quality: Use high-quality fuel and maintain proper fuel levels to ensure optimal performance.

- Storage Conditions: Store your equipment in a dry and protected environment to shield it from moisture and extreme temperatures.

- Scheduled Servicing: Adhere to a regular servicing schedule with a qualified technician to ensure all systems function correctly.

By following these maintenance tips, you can promote longevity and reliability, ensuring that your equipment remains in top condition for years to come.

Safety Guidelines for Effective Use

Ensuring a safe and efficient operation is crucial when handling any equipment. Adhering to safety practices not only protects the user but also enhances the overall performance of the tool. Awareness of potential hazards and preparation can significantly reduce the risk of accidents.

Before Usage: Always inspect the device for any signs of damage or wear. Ensure that all components are functioning correctly and securely attached. Familiarize yourself with the controls and features to understand how to operate the equipment safely.

During Operation: Wear appropriate personal protective equipment, including gloves, goggles, and sturdy footwear. Maintain a safe distance from bystanders and ensure a clear work area to prevent injuries. Stay focused on the task at hand and avoid distractions that could compromise safety.

Post-Operation Care: After completing your work, clean the equipment thoroughly and store it in a safe location. Regular maintenance checks can help identify issues early, extending the lifespan of the tool and ensuring optimal performance for future use.