Maintaining construction machinery requires careful attention to ensure optimal performance and longevity. Whether you’re dealing with daily operations or planning long-term care, understanding how to handle essential functions and procedures is crucial. This guide provides insights into the fundamental aspects of keeping your machinery in excellent condition, ensuring both safety and efficiency on the job site.

In this resource, you’ll discover key techniques and practical advice that will assist you in navigating through different maintenance tasks. From

Understanding the Hydraulic System

The hydraulic system is a crucial component in modern heavy equipment, ensuring smooth and efficient operation of various functions. Proper knowledge of this system is essential for both maintenance

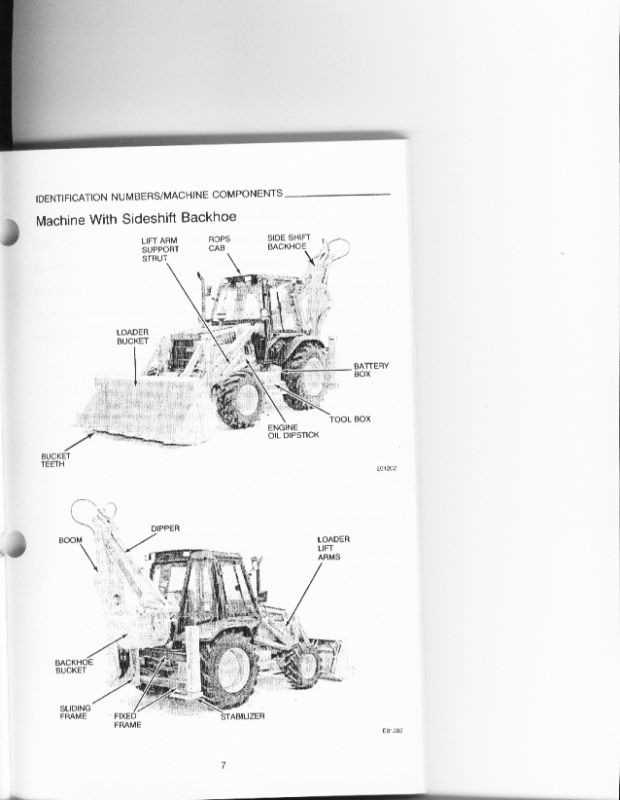

Key Components and Functions

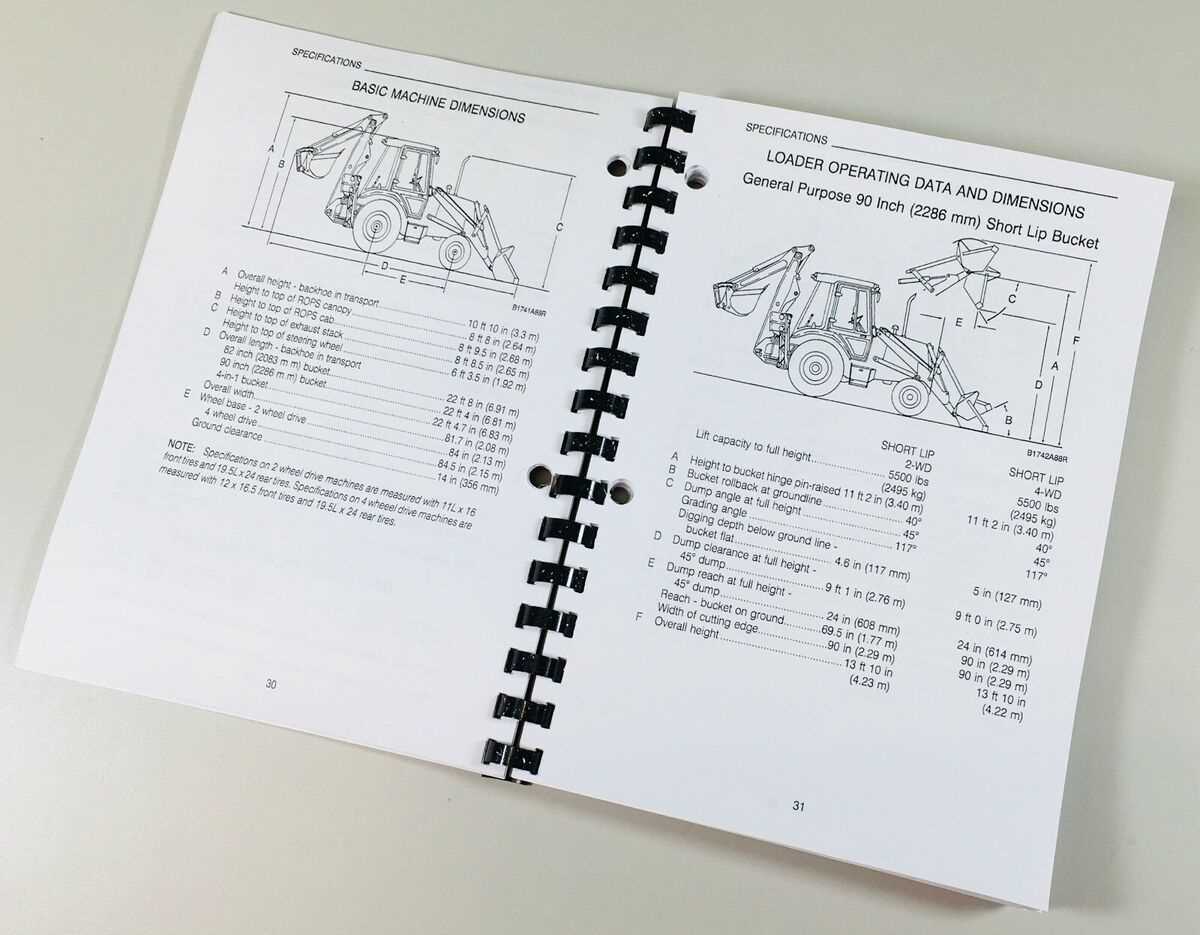

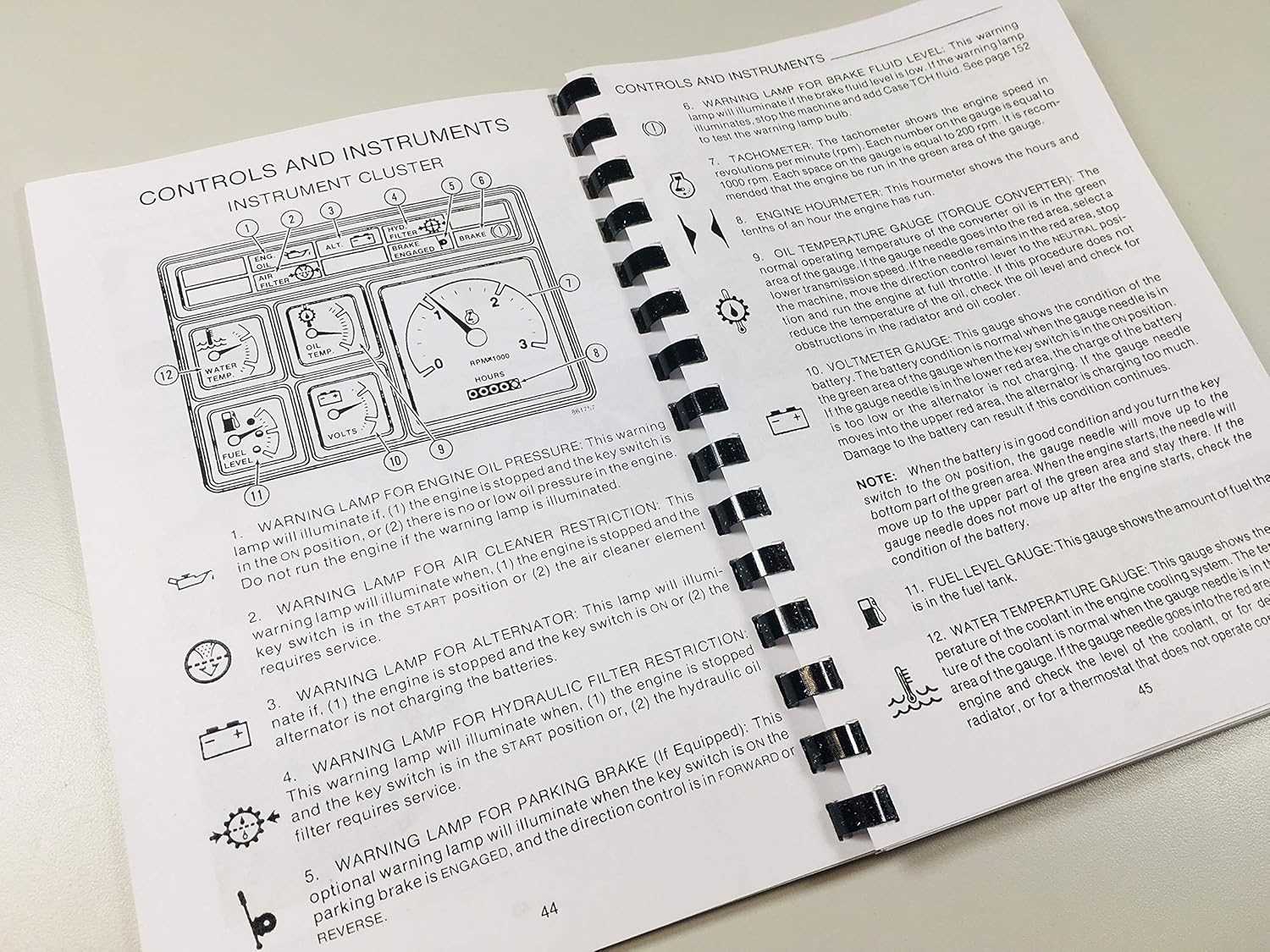

The following section provides a comprehensive overview of the essential parts and their respective roles in the operation of this heavy equipment. Understanding these elements is crucial for efficient usage, maintenance, and troubleshooting. Each component works together to ensure optimal performance and durability in a variety of tasks.

Engine and Powertrain

The power unit is the heart of the machinery, driving all systems with the necessary energy. The transmission system seamlessly converts this power, allowing for smooth movement and control across various terrains.

- Engine: Responsible for generating power and maintaining operational consistency.

- Transmission: Transfers power from the engine to the wheels, facilitating movement.

- Hydraulic System: Provides force to the equipment’s various attachments, enabling lifting, digging, and other mechanical actions.

Common Issues and Maintenance Tips

Regular maintenance is essential to ensure the longevity and smooth operation of heavy-duty machinery. Many recurring issues can be prevented through routine checks and timely servicing, which help to minimize downtime and costly repairs. Understanding potential problems and knowing how to address them effectively will keep equipment running efficiently.

Hydraulic System Troubles

One of the most frequent concerns is related to the hydraulic system. Leaks, unusual noises, or sluggish movement often indicate the need for immediate inspection. Maintaining proper fluid levels and checking for worn seals can help prevent serious damage. It’s crucial to regularly monitor the system and address minor issues before they escalate.

Engine Performance and Cooling

Engine issues can arise due to overheating, poor fuel quality, or lack of proper filtration. Overheating can damage critical components, so it’s important to keep the cooling system in top condition. Regular cleaning of radiators and ensuring that coolant levels are adequate can

Operating Procedures for Backhoe Loader

The proper operation of a backhoe loader is crucial for efficient and safe performance on any construction site. This section outlines the fundamental steps to follow when using the machinery, emphasizing safety, control, and productivity during various tasks. Understanding and adhering to these guidelines ensures smooth and effective operation while minimizing the risk of damage or injury.

Initial Preparation

Before beginning work, conduct a thorough inspection of the machine. Ensure that all fluid levels are sufficient, tires are properly inflated, and all moving parts are lubricated. It is vital to adjust the seat and controls to suit the operator’s comfort, as proper ergonomics can significantly improve both efficiency and safety.

Basic Operating Guidelines

Start the machine and allow it to warm up to its optimal operating temperature. When operating the loader, ensure smooth and controlled movements, especially when raising or lowering the bucket. For digging, use precise positioning to

Safety Guidelines for Efficient Operation

Ensuring safety during the use of heavy machinery is paramount for both operator protection and optimal performance. Adhering to established protocols not only reduces the risk of accidents but also enhances the efficiency of the equipment. This section outlines key practices that should be followed to maintain a secure working environment.

Familiarization with Equipment: Operators should possess a thorough understanding of the machinery’s functions and features. This knowledge is essential for making informed decisions during operation and troubleshooting potential issues.

Personal Protective Equipment (PPE): Wearing appropriate PPE, such as helmets, gloves, and safety boots, is crucial. These items provide necessary protection against injuries that may occur from equipment operation and environmental hazards.

Pre-Operation Inspection: Conducting a comprehensive inspection before using the machinery helps identify any potential malfunctions or hazards. Checking fluid levels, brakes, and other critical components ensures that the equipment is in safe working condition.

Safe Operating Procedures: Adhering to the recommended operating procedures minimizes risks. This includes understanding load capacities, maintaining a safe distance from obstacles, and utilizing proper techniques for maneuvering.

Emergency Preparedness: Operators must be aware of emergency protocols and ensure that safety equipment, such as fire extinguishers and first aid kits, is readily available. Regular training on emergency procedures enhances readiness for unforeseen situations.

Continuous Training: Ongoing education and training on safety practices are vital. Staying updated on the latest safety guidelines and operational techniques can significantly reduce the likelihood of accidents.