Understanding the intricacies of your table saw can greatly enhance your woodworking projects. This resource aims to provide essential insights and practical information to help you maximize the potential of your equipment.

By exploring various features and operational guidelines, users can ensure safety and efficiency during each task. Whether you are a seasoned professional or a novice, having access to thorough instructions will ultimately lead to improved craftsmanship.

From setup procedures to maintenance tips, this guide serves as a valuable tool for anyone looking to delve deeper into their woodworking experience. Embracing these practices will not only enhance performance but also prolong the lifespan of your machine.

Understanding the Dewalt DW745 Features

This section will delve into the distinctive characteristics and functionalities of a renowned portable table saw, designed for both professionals and DIY enthusiasts. Grasping these features can enhance your woodworking experience and improve efficiency on the job site.

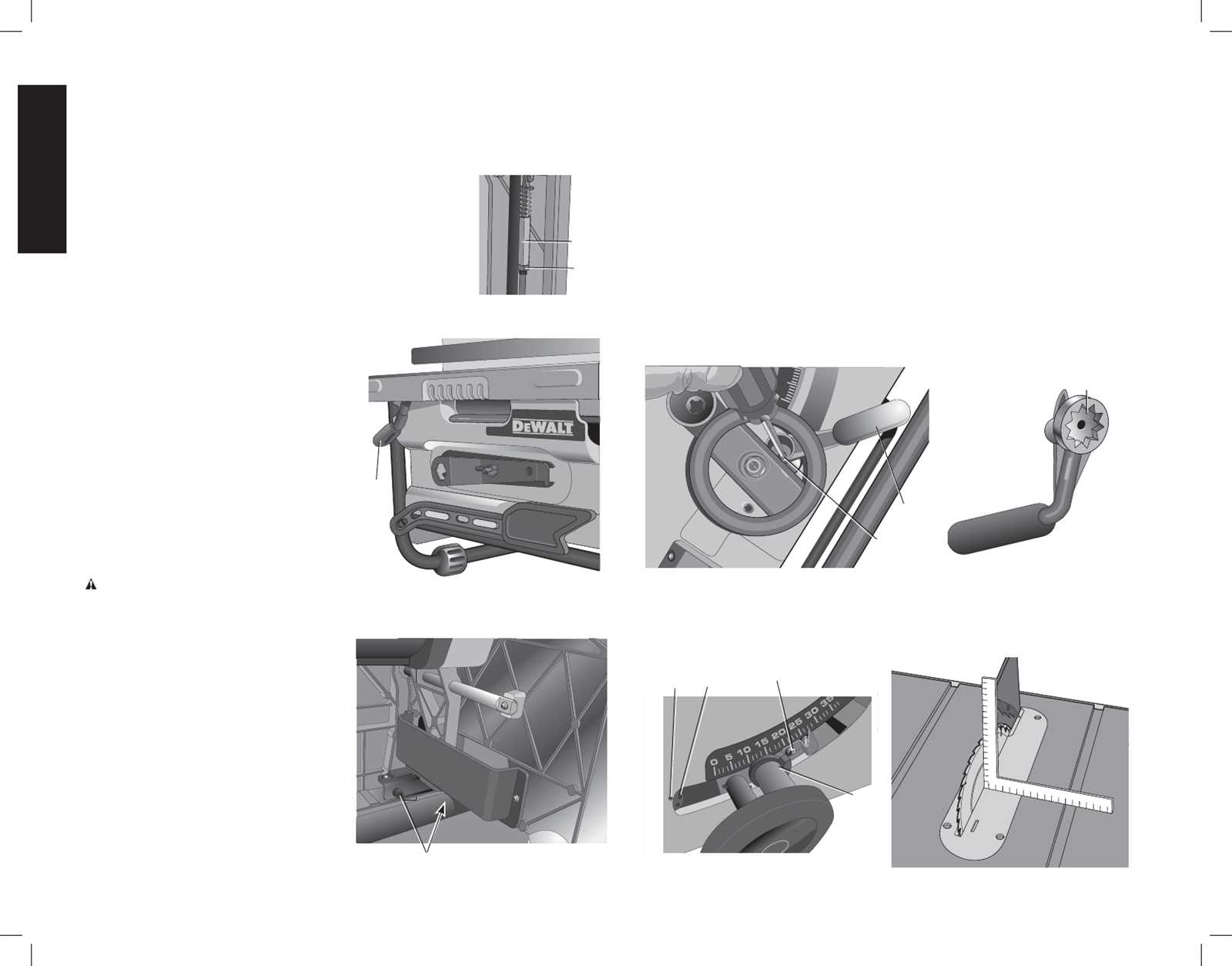

- Compact Design: The saw is engineered for easy transport and storage, making it ideal for job sites with limited space.

- Powerful Motor: Equipped with a robust motor, this tool delivers high performance for various cutting tasks, ensuring clean and precise cuts.

- Adjustable Blade Height: The blade height can be easily adjusted, allowing users to make different cuts with accuracy.

- Bevel Capacity: The unit features a bevel capacity, enabling angled cuts, which adds versatility to your projects.

- Safety Features: It includes several safety mechanisms, such as blade guards and riving knives, to protect users during operation.

Understanding these attributes can help users maximize the potential of this equipment and ensure a safer, more productive work environment.

Maintenance Tips for Long-lasting Performance

To ensure optimal functionality and extend the lifespan of your equipment, regular upkeep is essential. Adopting a few simple practices can significantly enhance performance and reliability over time.

Regular Cleaning

- Remove dust and debris after each use.

- Use a soft brush or compressed air for hard-to-reach areas.

- Check for any blockages in ventilation ports.

Routine Inspections

- Examine electrical cords for fraying or damage.

- Inspect blades and bits for wear and replace as necessary.

- Ensure all moving parts are lubricated properly.

Common Troubleshooting Techniques for Users

When operating power tools, encountering issues can be frustrating. However, understanding basic troubleshooting techniques can help users identify and resolve common problems effectively. This guide outlines some essential methods to assist in maintaining optimal performance and extending the lifespan of your equipment.

Identifying Power Issues

One of the first steps in troubleshooting is to check for power supply problems. Ensure that the device is plugged in securely and that the outlet is functioning. Additionally, inspect any extension cords for damage and verify that the circuit breaker hasn’t tripped. Proper maintenance of electrical components is crucial for seamless operation.

Addressing Mechanical Concerns

If the tool is not functioning as expected, examine its moving parts for any obstructions or wear. Regularly cleaning and lubricating components can prevent jams and ensure smooth operation. Listening for unusual sounds during use can also indicate potential mechanical failures that require immediate attention.