When operating any equipment, it is crucial to understand its full potential and ensure safe and efficient handling. This guide offers key insights into how to maximize performance while maintaining proper care and operation.

From fundamental maintenance practices to advanced operational techniques, you’ll find valuable information to help you make the most of your machinery. Proper care will not only extend the life of the equipment but also enhance its daily functionality.

In the following sections, we’ll explore essential safety measures, detailed steps for upkeep, and best practices to ensure your machine remains in top condition for years to come.

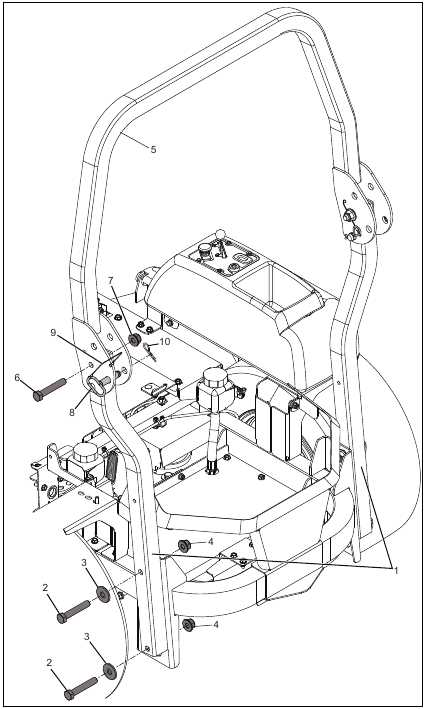

Essential Maintenance for Zero-Turn Mowers

Regular upkeep is crucial to ensure the longevity and performance of your zero-turn mower. Proper care and attention to key components will help maintain its efficiency and avoid costly repairs. Understanding the routine tasks that keep the machine in optimal condition is vital for its long-term durability.

Engine care involves regular oil changes and ensuring the air filter remains clean. A well-maintained engine ensures smooth operation and prevents overheating. Make sure to check oil levels before each use and replace the filter as needed.

Blade maintenance is another critical aspect. Keeping the blades sharp ensures an even cut and reduces stress on the mower’s engine. Dull blades can tear grass rather than cut it, causing damage to your lawn and the machine itself.

Additionally, tire pressure should

Understanding the Importance of Regular Service

Routine maintenance is essential for ensuring the longevity and efficiency of any equipment. Consistent servicing helps in identifying potential issues early, reducing the likelihood of unexpected breakdowns, and ensuring optimal performance over time. By regularly checking and maintaining the different components, the chances of costly repairs and downtime are minimized.

Key Benefits of Consistent Maintenance

Maintaining equipment regularly provides numerous advantages, including improved safety, extended operational lifespan, and enhanced productivity. Neglecting service intervals can result in decreased efficiency, higher fuel consumption, and increased wear on parts, leading to premature failures.

Components to Focus on During Service

| Component | Recommended Action | Frequency |

|---|---|---|

| Engine | Oil change, filter replacement | Every 50 hours

Troubleshooting Common Issues

Regular use of any machine can lead to occasional challenges that need to be addressed for optimal performance. Identifying potential problems early on can save time and prevent more significant issues down the road. Below are some frequent complications that users may encounter, along with practical solutions to help resolve them. Engine Starting Difficulties

If the machine is having trouble starting, the first step is to check the fuel system. Ensure there is sufficient fuel, and that it is clean and fresh. Old or contaminated fuel can prevent the engine from turning over. Additionally, inspect the spark plug for wear or dirt buildup, as this can also cause startup issues. Replacing or cleaning the plug can often restore normal function. Uneven Cutting Performance

When the machine leaves patches of uncut grass or shows uneven cutting patterns, this may be due to blade wear or improper deck leveling. Regularly inspecting and sharpening the blades can help maintain consistent cutting quality. Additionally, checking the tire pressure ensures that the machine is balanced, which contributes to even cutting across all areas. Optimizing Performance and Longevity

To ensure that your equipment remains efficient and lasts for years to come, it’s crucial to follow specific practices that enhance its functionality and durability. Regular attention to key components and timely adjustments can significantly extend its lifespan while maintaining high performance. Begin by consistently inspecting moving parts, tightening any loose bolts, and ensuring that fluids are topped off and clean. Proper lubrication is essential for reducing wear and tear. Routine checks will prevent minor issues from becoming costly repairs down the line. Another important factor is keeping the equipment clean. Dirt and debris can clog mechanisms, reducing their effectiveness. Frequent cleaning, particularly after intensive use, will help maintain optimal working conditions. Finally, adhere to recommended usage limits. Overloading or using equipment in unsuitable conditions may strain components, leading to premature failure. By operating within the designated guidelines, you’ll preserve the machine’s reliability and efficiency for longer periods. |