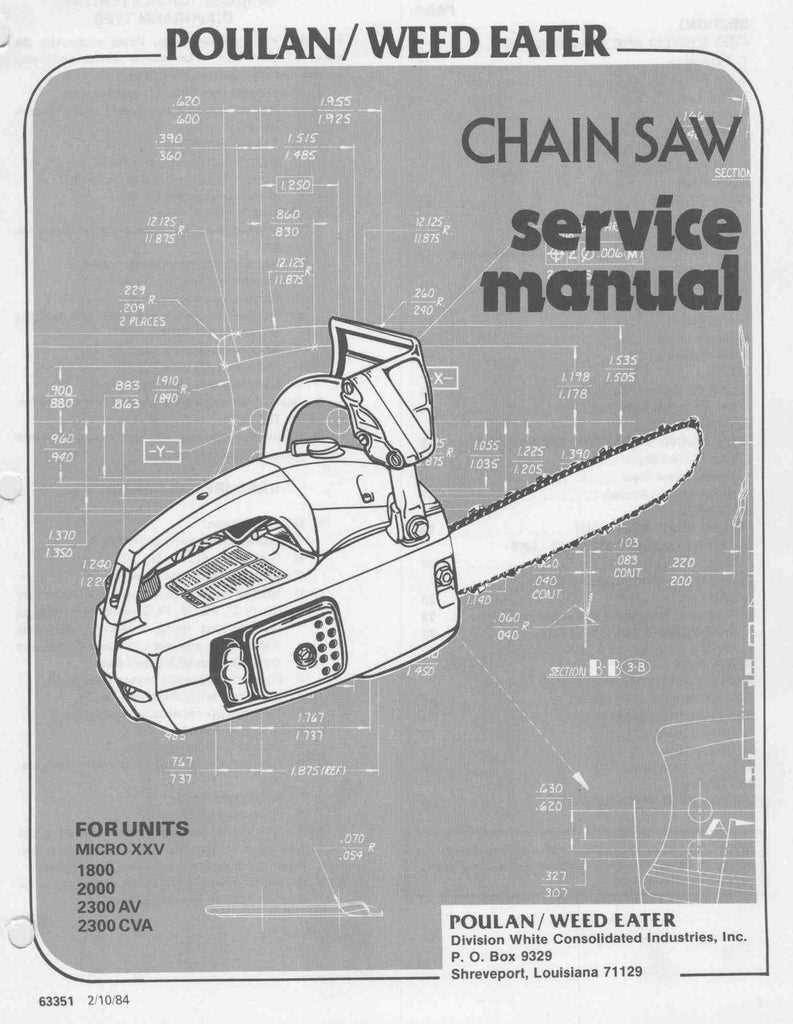

Understanding the proper use and upkeep of your cutting tool is essential for safe and efficient performance. This section will provide detailed insights into various aspects of handling and maintaining your device, ensuring its longevity and smooth operation.

By following the guidelines outlined here, you will learn key maintenance techniques, as well as safety precautions that are crucial for preventing wear and tear. These instructions will also cover steps for troubleshooting common issues, helping you keep your equipment in optimal condition for any task.

Whether you’re new to using this kind of tool or have years of experience, these recommendations will enhance your ability to handle it with confidence and precision.

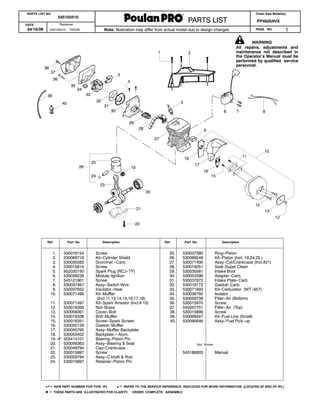

Tool Maintenance Tips

Regular upkeep is essential to ensure the longevity and performance of your equipment. Proper care not only extends the life of the device but also ensures it operates efficiently and safely.

- Clean the air filter frequently to prevent debris buildup, which can affect performance.

- Check and sharpen the cutting edge regularly for smoother and more efficient operation.

- Inspect the fuel system for leaks or clogs to ensure proper fuel flow.

- Lubricate all moving parts to reduce wear and tear over time.

- Ensure all bolts and screws are tightened to avoid any loose components during use.

Following these steps will help keep your device in optimal condition and ready for any task.

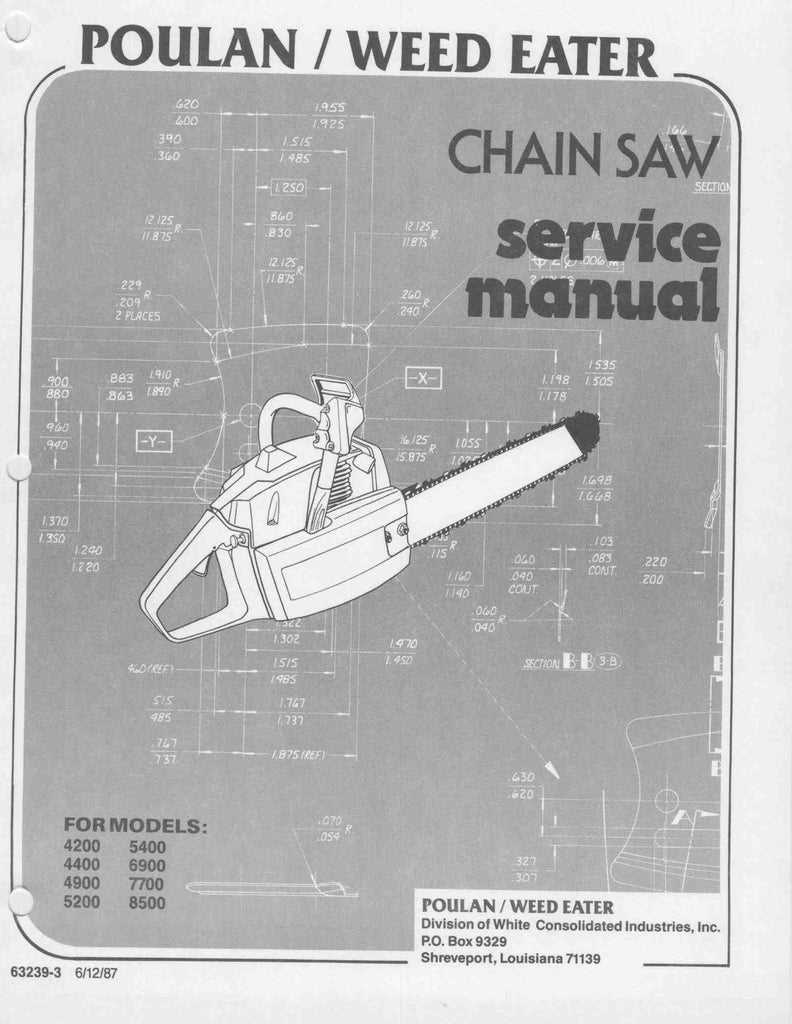

How to Troubleshoot Common Chainsaw Issues

Identifying and resolving frequent mechanical problems can help ensure optimal tool performance. Many challenges are simple to diagnose and fix, requiring only a basic understanding of the equipment and some attention to detail. Here’s how you can tackle the most common malfunctions.

Starting Problems

If your machine won’t start, it could be due to several causes. Begin by checking the fuel level, as empty tanks are a frequent issue. Also, inspect the spark plug for wear or dirt, as this can prevent proper ignition.

- Ensure the fuel tank is full.

- Clean or replace the spark plug if necessary.

- Check the choke settings and adjust accordingly.

Chain and Bar Issues

A dull or loose chain can reduce cutting efficiency and even damage the tool. Keeping the chain sharpened and properly tensioned is essential for smooth operation. Regularly inspect the guide bar for any signs of wear.

- Tighten the chain if it’s too loose.

- Sharpen the chain to maintain cutting performance.

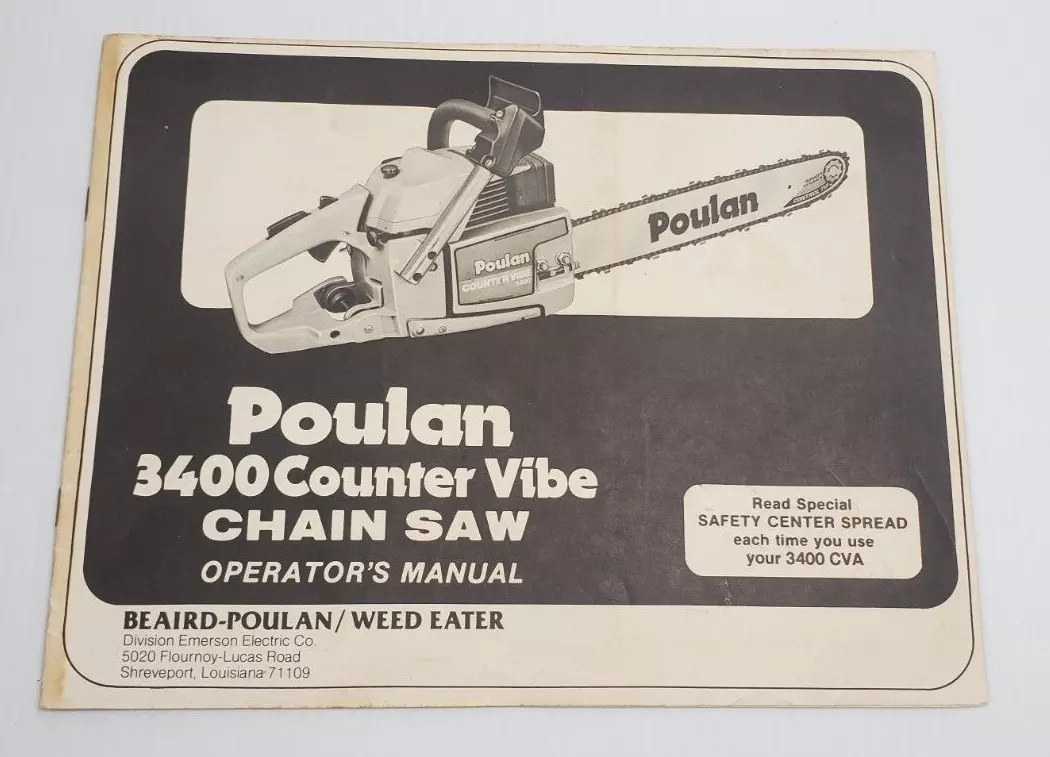

Safety Guidelines for Using Cutting Tools

When operating powerful cutting equipment, it’s crucial to prioritize safety to prevent accidents and injuries. This section highlights essential practices to ensure secure and effective tool usage.

- Always wear protective gear, including gloves, safety goggles, and sturdy boots to minimize the risk of injury.

- Inspect the equipment before each use to ensure all components are functioning properly and securely attached.

- Clear the working area of any obstacles or debris to prevent tripping or interference during operation.

- Maintain a firm grip and stable stance while handling the tool, especially during prolonged tasks.

- Follow proper fueling and maintenance procedures to avoid potential malfunctions or dangerous situations.

By adhering to these precautions, you can ensure a safer and more efficient work experience with your cutting tools.