Maintaining your machine in optimal condition is crucial for ensuring its long-lasting performance. Regular care and attention can prevent potential issues and keep the equipment running smoothly, enhancing its efficiency.

Paying attention to specific components that are responsible for the overall operation is essential. By

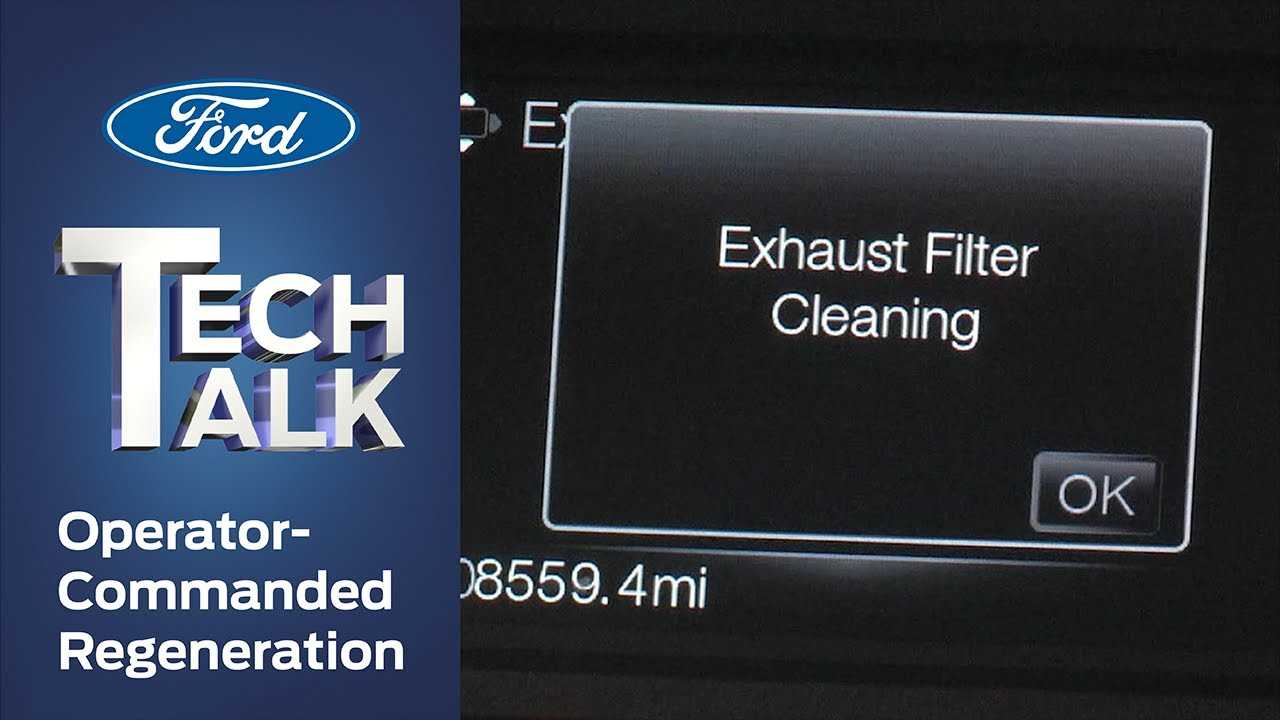

Exhaust Filter Maintenance Instructions

Proper upkeep of specific vehicle components is crucial for ensuring smooth operation and longevity. Periodic attention to these areas can prevent larger issues and maintain efficiency in your system’s performance. Regular inspection and necessary care can optimize the overall function of your equipment, ensuring it runs as expected.

| Step | Description |

|---|---|

| 1 | Identify the area where airflow is directed and remove any visible obstructions. |

| 2 | Inspect the surface to detect buildup or residue that may hinder performance. |

| 3 | If needed, gently remove unwanted particles using appropriate tools. |

| 4 | Reassemble the unit, ensuring all parts are properly secured for optimal functionality. |

How to Clean and Care for the Filter

Maintaining your equipment involves routine upkeep of its components to ensure optimal performance. By dedicating time to regular attention, you can extend the life of your machine and avoid potential issues.

Preparation and Essential Steps

Before starting, ensure that the device is completely turned off and safely disconnected from power. Gently remove the key part that requires attention, making sure to handle it carefully to prevent any damage.

Handling and Routine Upkeep

Once removed, it’s important to ensure that no debris or particles are left behind. You may use appropriate tools or methods to address this without causing harm to the equipment. After finishing, reassemble everything properly to keep the machine running smoothly.

Common Issues with Exhaust Filters

Devices that rely on air circulation for optimal performance often face certain recurring problems related to their airflow systems. Over time, parts responsible for maintaining clear passageways can encounter obstructions, which affects the overall efficiency and can lead to performance degradation.

Reduced Performance

One of the most common problems is a noticeable reduction in operational efficiency. When internal pathways are partially blocked, the device may start working harder to achieve the same results, leading to increased energy consumption and lower overall output.

Frequent Maintenance Needs

Another issue is the increased need for regular upkeep. Blockages or impediments in the system often demand more frequent attention, requiring users to perform periodic check-ups to ensure smooth functionality and prevent long-term damage.

Best Practices for Filter Longevity

Maintaining the functionality of essential air components is crucial for ensuring long-lasting performance and efficiency. Implementing effective habits can significantly extend the lifespan of these parts, contributing to a more reliable and sustainable operation. By following simple yet impactful strategies, you can reduce wear and ensure optimal conditions over time.

Regular Monitoring and Maintenance

Scheduling consistent evaluations and upkeep routines helps identify potential issues early. Checking the state of key elements at appropriate intervals ensures they continue to operate under ideal conditions, preventing unexpected malfunctions.

Environmental Considerations

External conditions, such as the quality of the surrounding air and exposure to contaminants, can affect the overall durability of internal systems. Adjusting practices based on environmental factors can prevent premature wear and ensure the longevity of the core components.

| Maintenance Task | Frequency |

|---|